Bag filter design calculations equipment nature. Total collection efficiency sample calculation particle size range particle size fractional efficiencies microns distribution d50 collection collected particulate min max by weight.

Pile Cap Design For Piles Spreadsheet Spreadsheet Cap Design Cap Designs

The first phase is sizing your duct work for adequate volume and velocity of flow for.

. Designing Your Dust Collection System. Manufacture - To produce prepare or compound a priority. The content of this site is to be seen as a help and important information and.

StaticCalc Duct Sizing Calculator - Free download as Excel Spreadsheet xls PDF File pdf Text File txt or read online for free. If a machine has multiple dust ports the total CFM for the machine is the sum of all of the ports. Then Click on Calculate To Find the Interstitial Velocity.

Ug is the gas viscosity at the Collector inlet in lbft-sec S is the true specific gravity of the dust at the collector inlet equal to the true density in grams per cc The fractional efficiency is found by. Desired location of dust collector unit. Excel and other spread sheets are used to calculate and optimize dust collection equipment parameters.

42 Calculate the following geometrical dimensions. Metalworking Machinery Tooling and Accessories for All Industrial Shop Needs. Has designed and manufactured standard and custom dust collection systems for customers around the world.

Draw a Top-Down View Sketch to Scale Of Your Machines and Dust Collector. 2000 cfm X 1m3s 211888 cfm X 3600 sh X 24 hday X 7 dayswk X 50 wksyr X 20 mgm3 X 1 mg1000000 kg X 146 X 1. Ad Our Metal Dust Collector Helps Keep Your Shop Clean.

A e product inlet section area m2 A i gas outlet section area m2 R i radius of gas outlet pipe m r e average radius of the. Suction Air Quantity Q 1000 m3hr. Draw a floor plan of your shop 2.

Productivity comply with emission regulations and improve industry employee m orale. Industrial Systems Benches Cyclones and Portables. Floor to joist measurement.

Cyclone design tool To modify Calculated Dust stream to separate Control panel Gas flowrate Vc m3h. We Have Heavy Duty Portable Systems. Count 05 for each 45 degree bend and 10 for each full 90.

Designing Woodworking Shop Power Point 3 Author. You are not limited to one type but can enter a mix of. Dust Collection Air Flow Requirements.

RD is the ratio of the bends centerline radius divided by the pipe diameter. Designing Your Dust Collection System There are five simple steps to designing an effective and efficient dust collection system. Enter ACFM of Air Side L in Side w in - Bag Dia2² π of Bags.

There are two phases to designing your dust collection system. Design Margin 25Air Quantity Q 1250 m3hrMaterial factor f 2. The first phase is.

Ad Provent Wet Dust Collection System Is The WorldS Most Advanced Wet Dust Collector. For over 40 years US. A 1 P 1 x 4in144 2 x 202190190216 x 4 144 44 sqft.

Dust collection system has multiple benefits resulting in a dust-free envir onment that increases. Put accurate system performance information at your fingertips to make smarter decisions. Remember Machines with the biggest draw highest CFM should be placed nearest to the dust collector.

Ad Read the 5 valuable metrics from a connected dust collector that can make your job easier.

Dust Collector Systems Design And Calculation Tutorials Youtube

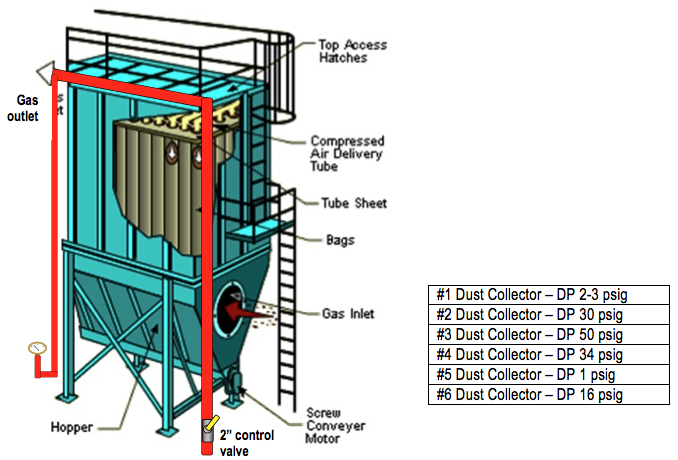

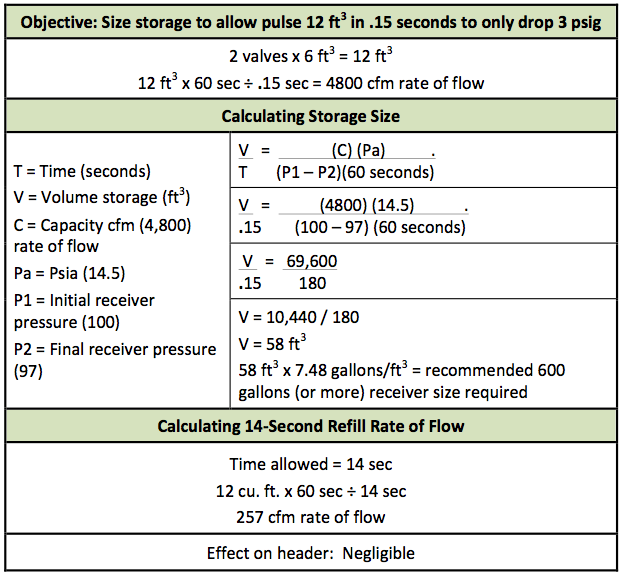

Maximizing Dust Collection System Efficiency Compressed Air Best Practices

Maximizing Dust Collection System Efficiency Compressed Air Best Practices

.jpg)

System And Ducting Design Scientific Dust Collectors

0 comments

Post a Comment